Did you know that you can navigate the posts by swiping left and right?

Venting a Gene Cafe Coffee Roaster

17 Jan 2018 . Category . Comments #hardware #diy

A Gene Cafe is an excellent little coffee roaster I’ve used for years. A real advantage of this roaster if you don’t have a garage is that you can vent the exhaust. Over the years, people have asked me exactly how I do this, so here’s a post.

This is what the final assembly looks like from the front:

and from the side:

I’ll walk you through the various pieces in the same order you’d assemble them. That’s right, assemble, because I don’t leave this set up all the time.

I assume windows with a vertical sash. First, we use a 2x2 piece of wood that rests in the sash track to raise the base of the assembly high enough that the rest of the window does not touch or interfere with the hot vent pipe:

The base should be cut as closely as possible to the length of the track to prevent exhaust smoke from blowing back through any cracks. Small opennings are ok; big opennings you can put multiple fingers through are not ok.

The next piece is the foam insulator. This piece surrounds the exhaust pipe and forms a seal with all other contact surfaces. The material is 1-2 inch foam weatherstripping for AC window units, like this. The exact diameter doesn’t really matter. It just needs to be substantial enough for the application. I cut it to the size of the window in two strips, duct taped them together (camo tape is how I roll), and cut a notch for the pipe. The notch can be undersized because the foam will compress to fit. The idea is no air gaps:

The window sash is heavy, and you don’t want it supported by the exhaust pipe. That could distort the shape of the pipe, and more significantly it will move the pipe out of position. To carry the weight, I cut two small holes vertically in the foam and inserted PVC pipe, probably 1/2 inch but maybe 3/4 inch. Cut it so that it is just under the height of the foam when there’s no compression, so that the pvc will allow some compression to occur:

Finally we have the exhaust pipe assembly. It has two parts that I keep together in storage:

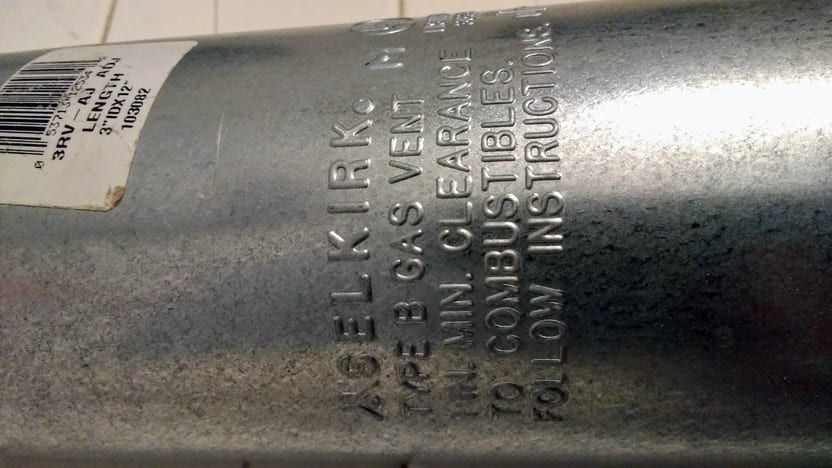

One part is a double walled exhaust pipe, I think designed for water heaters. This keeps the outer surface cool, which is good, because it touches the foam and gets close to various parts of the window:

The other part is the pipe/hose. I think this is just metal dryer vent hose. Notice it has an adjustable ring to fit to the Gene Cafe. That only needs to be adjusted once to keep a decent fit and protect the pipe edges from fraying. Don’t overtighten or you could break your roaster!

The two pipe assembly pieces fit together easily. Quite a bit of the pipe is pushed onto the inner wall of the tube, where it is held in place by compression. Did I say I like compression?

After you roast, the pipe will be very hot to the touch even though the tube is fine. I suggest letting it all cool off before disassembly and storage. You want to let the roaster cool off to empty the chaff collector anyways.